Story of the electronic stability program (ESP) | Premiered by Mercedes-Benz in 1995

25 years ago, Mercedes-Benz and Bosch jointly developed the electronic stability program (ESP) and the S 600 Coupe was the first production car launched with it

Testing of the first ever ESP for a series production vehicle in Arjeplog, Sweden in 1994

Testing of the first ever ESP for a series production vehicle in Arjeplog, Sweden in 1994Modern cars are equipped with numerous electronic safety aids. One of them is the electronic stability program (ESP) that helps the driver gain better control of the car in extreme driving conditions. For the uninitiated enthusiasts, that’s the beep and the ESP sign in the instrument cluster that alerts you after sliding your car on gravel. This critical safety feature is now ubiquitous across global car brands, and all of them have their own abbreviations for the same (ESC, VSC and PSM among others) but the first brand ever to launch it was Mercedes-Benz in the 1995 S 600 Coupe.

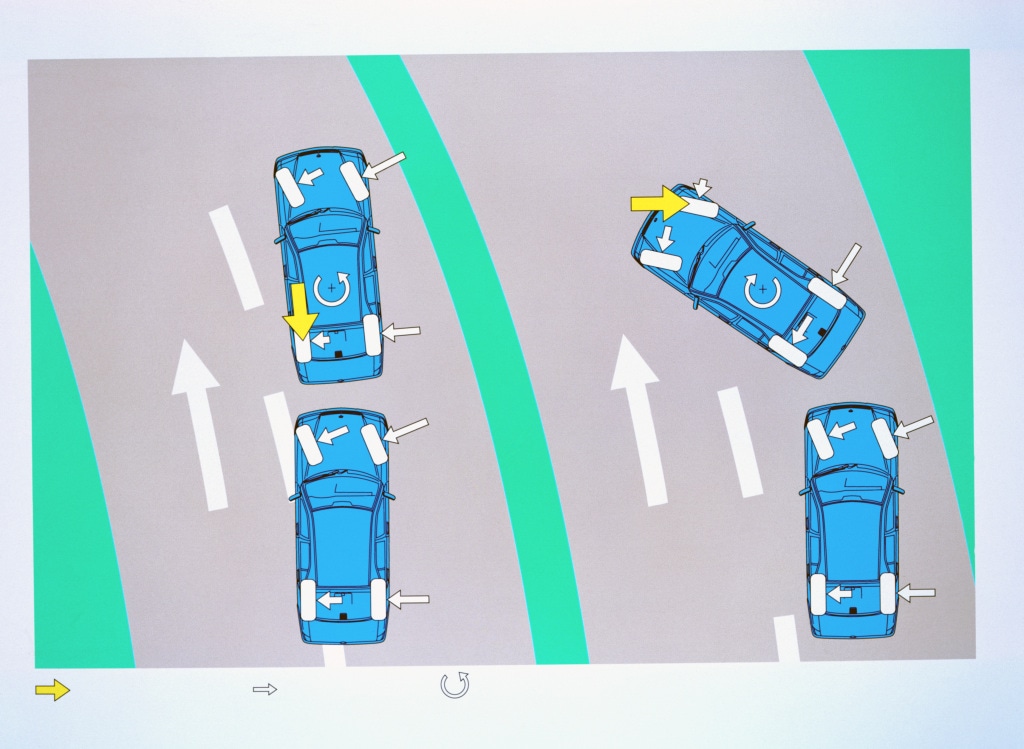

ESP can restrict understeer and oversteer in extreme conditions

ESP can restrict understeer and oversteer in extreme conditionsHow does ESP work?

Electronic stability program (ESP) alters the vehicle’s braking and torque to individual wheels for better dynamic control in extreme conditions, especially slippery ones. It’s based on the successful anti-lock braking system (ABS) and anti-slip control (ASR) technologies, but uses a more extensive set of sensors that detect steering angle, lateral acceleration and yaw rate sensors apart from the standard wheel speed and wheel slip sensors.

The yaw rate sensor is particularly a key component in ESP. Developed by Bosch, the yaw rate sensor accurately detects the vehicle’s rotational motion about its vertical axis and then the system applies corrective braking within milliseconds to avoid skidding. Through the 1980s and 1990s, Toyota, Mitsubishi and BMW were also at the forefront of this development, having developed their own anti-skid and traction control systems. But the crucial yaw input was missed out on.

Tiny components of ESP make a big difference in the way a car drives

Tiny components of ESP make a big difference in the way a car drivesThe 'moose' crash test incident

A key incident triggered a major safety transformation for Mercedes-Benz in 1997. A test designed to assess the capability of the W 168 A-Class to perform evasive manoeuvres was conducted with a Swedish motoring journalist behind the wheel. At 60kmph, the A-Class unexpectedly overturned while going through the slalom, raising many questions over its safety and stability through bends. It was considered a failure by many but the top management at Mercedes-Benz showed urgency to resolve this challenge.

Deliveries of the A-Class were postponed for 12 weeks and all W 168 model series A-Class units sold till then were recalled. ESP, that was only fitted in select high-end Mercedes-Benz cars so far was now retrofitted to all the W 128 cars as a standard component and the A-Class now fared better than its competitors, even in extreme tests. In 1999, Mercedes-Benz became the first carmaker to fit ESP in all its passenger cars as a standard safety feature, sending signals to the entire automotive industry to undertake similar measures.

The A-Class fitted with ESP being rigorously tested after the moose test accident

The A-Class fitted with ESP being rigorously tested after the moose test accidentAlongside seatbelts, airbags and ABS, ESP has established itself as the most important safety feature in modern cars. Its effectiveness is proven. Data from multiple international highway authorities suggests that cars with ESPs were involved in fewer accidents compared to ones without it. Basic safety features like airbags and ABS were made mandatory for cars sold in India only recently, but we hope that features like ESP are also considered as standard equipment for a safer future of Indian motorists.