First new Bentley 1928 Blower revival engine fires up

The newly built engines, exact recreations of the original 1928 supercharged 4½-litre design, will first undergo testing before being married to a period-correct chassis

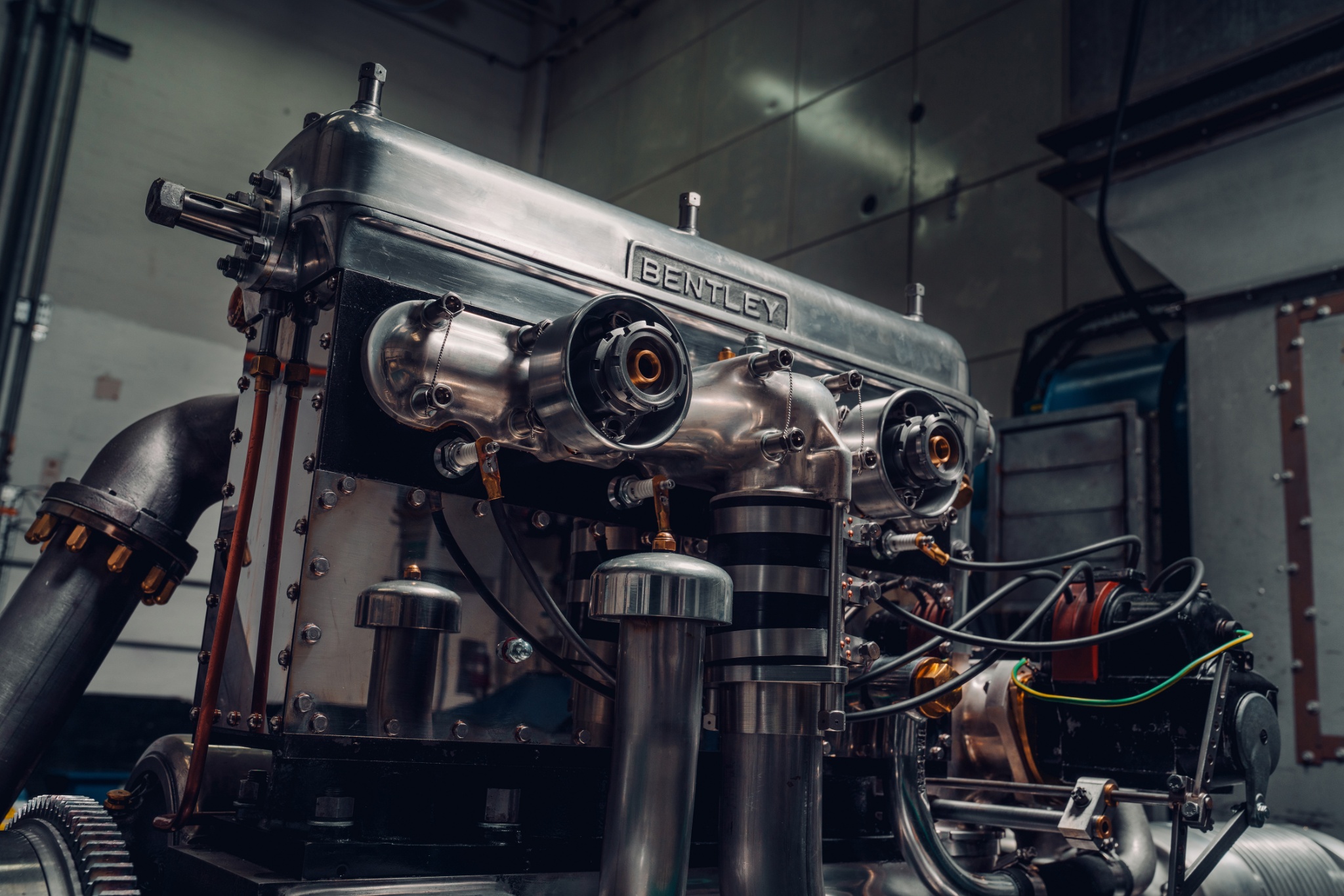

A hallowed badge, even after all these years!

A hallowed badge, even after all these years!The Bentley Mulliner’s Blower Continuation Series has come another step closer to reality, as the engine for car one of 12 was fired up for the first time on a dedicated and specially prepared testbed at Bentley’s Crewe factory. The Blower Continuation Series is a rerun of sorts for perhaps the famous Bentley of all time – the supercharged 4½-litre ‘Blower’ created for racing by Sir Tim Birkin in the late 1920s. Forming the world’s first pre-war continuation series, these 12 cars have all been pre-sold to die-hard Bentley collectors and enthusiasts worldwide.

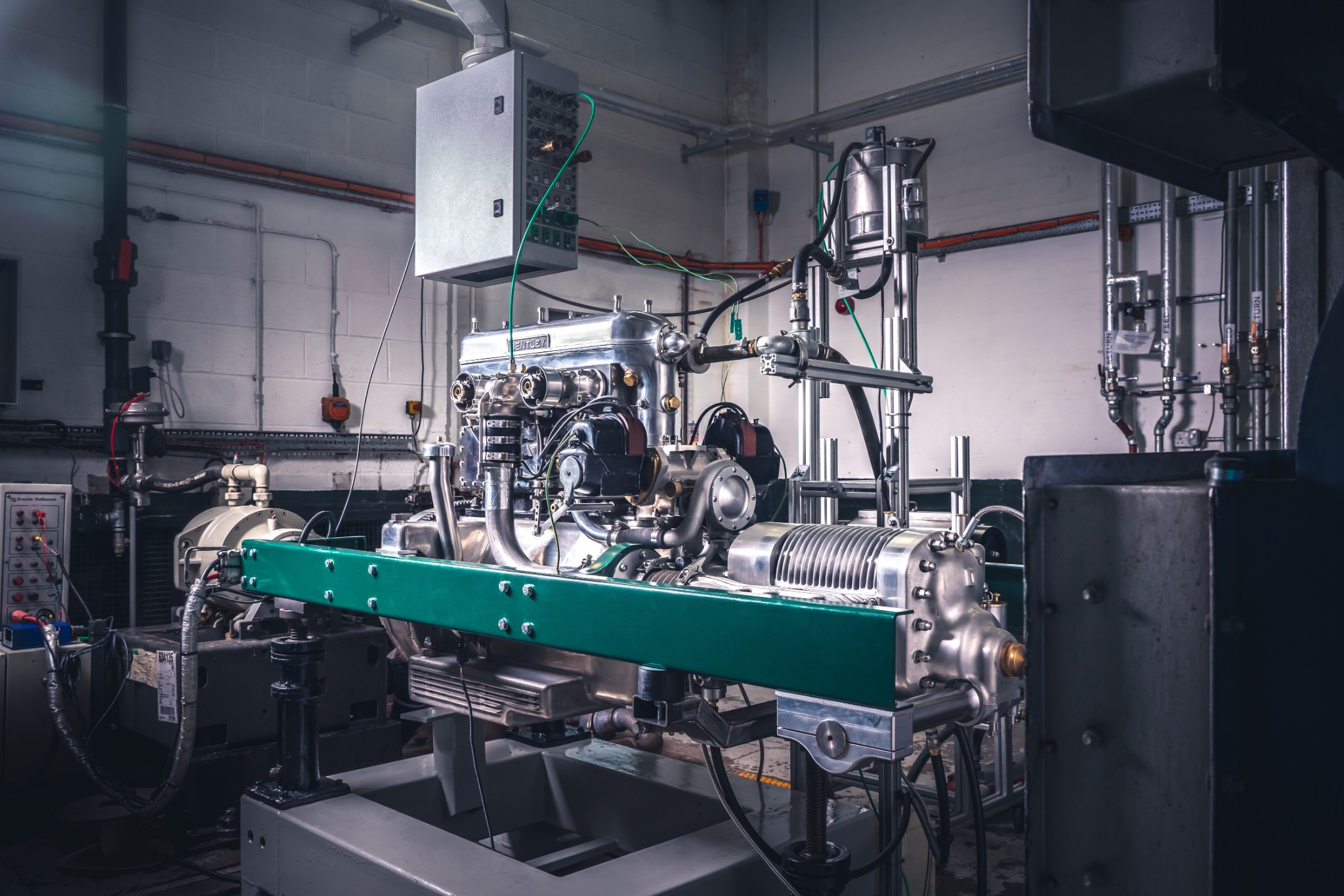

With the engineering prototype for the project – Car Zero – in build, a team of Bentley engineers began work to prepare one of the four engine development testbeds at Bentley’s Crewe headquarters to receive the engine. The engine test facility has been at Bentley since the factory was built in 1938, where it was originally used to run-in and power-test the Merlin V12 aero engines produced by the factory for the Supermarine Spitfire and Hawker Hurricane fighter aircraft from World War 2.

The blower engine is derived from the one used in World War 2 era fighter aircrafts

The blower engine is derived from the one used in World War 2 era fighter aircraftsPreparing the test bed involved making a replica Blower front chassis to hold the engine, which was then mounted to a dynamometer, allowing Bentley’s engineers to monitor the engine to precise parameters. As the Blower powertrain differs completely with Bentley’s modern production engines, a number of the original Merlin testbed fixtures – still in storage at Bentley HQ – were utilised to adapt the testbed to accommodate these special engines.

The first fire-up concluded two weeks ago, and the first engine is well on its way to a full power test across a 20-hour cycle, gradually increasing both engine speed and load conditions from idle to 3500 rpm. Once each engine is fully run in, a full-load power curve will be measured, after which Car Zero’s engine will be tested for real world durability. When the build of the car is complete it will start a programme of track testing – running for sessions of gradually increasing duration and speed, checking functionality and robustness under ever harder conditions. The test programme is designed to achieve the equivalent of 35,000km of real-world driving across 8000km of track driving, and simulates the undertaking of famous rallies such as Peking to Paris and the Mille Miglia.

After testing on the dyno, the engine will be installed in a specially built chassis for rigorous testing on track

After testing on the dyno, the engine will be installed in a specially built chassis for rigorous testing on trackThe Supercharged 4½-Litre Engine

The newly created Blower engines are exact recreations – down to the use of magnesium for the crankcases – of those that powered Tim Birkin’s four Team Blowers cars from the late 1920s. Each engine started life as the naturally aspirated 4½-litre engine, designed by WO Bentley (the founder of the Bentley brand) himself. Like Bentley’s 3-litre before it, the 4½-litre brought together the latest individual engine technologies of the time – a single overhead camshaft, twin-spark ignition, four valves per cylinder and, of course, Bentley’s now legendary aluminium pistons.

The racing version of WO’s 4½-litre engine developed approximately 130bhp, but ‘Bentley Boy’ Sir Tim Birkin wanted more. WO’s focus was always on reliability and refinement instead of absolute power, so his solution to finding more power was always to increase engine capacity. Birkin had a different plan – that of supercharging the 4½, an idea WO was not too happy with.

Hence, with funding from British equestrian and motorsport financier (and occasional racer) Dorothy Paget, and the technical skills of legendary engineer and racing driver Clive Gallop, Birkin commissioned supercharger specialist Amherst Villiers to create a supercharger for the 4½. The Roots-type supercharger – colloquially called a blower – was fitted ahead of the engine and radiator and driven directly via the crankshaft. Internal modifications to the engine included a reinforced crankshaft and connecting rods, and a modified oil system.

In racing tune, Birkin’s new supercharged 4½-litre engine was outputting around 240 bhp, making the ‘Blower Bentleys’ extremely fast, but as WO predicted, not particularly reliable. The Blowers played their part in Bentley history, including helping to secure victory for a naturally aspirated Bentley Speed Six at Le Mans in 1930, but over the 12 races that the Blowers contested, a victory was never secured.